India Requires $10 Billion Investment To Meet Domestic Li-Ion Battery Demand By 2030: Arthur D Little Study

- 70% of current Li-ion cell demand met via imports

- Major investments required in R&D and material sourcing to meet domestic demand

- Li-ion cell demand in India to rise to 70 GWh by 2030

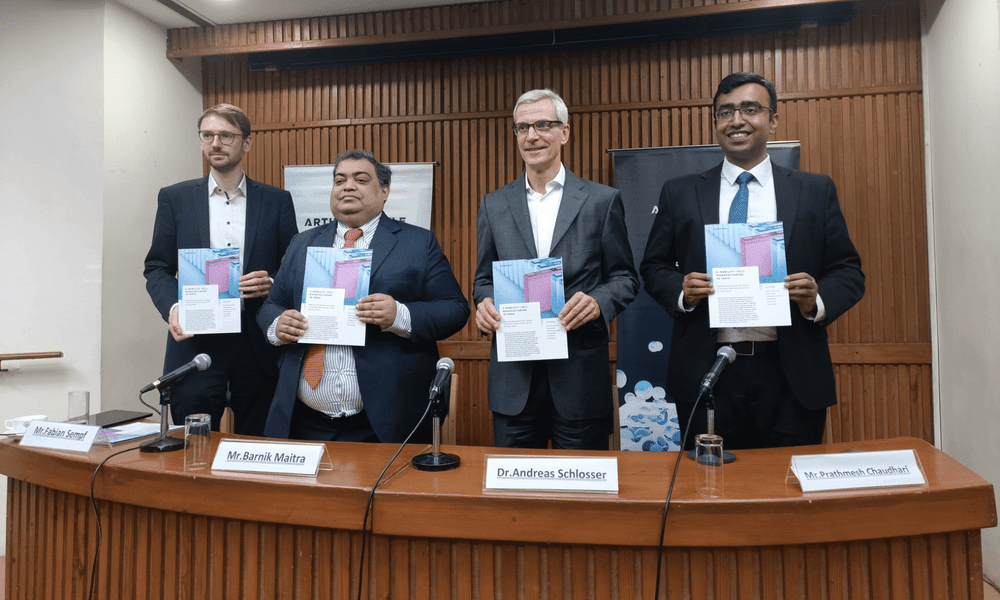

In a recent report published by Arthur D Little titled “e-Mobility: Cell Manufacturing in India” the consultancy firm highlighted that India would require substantial investments to meet local EV battery demand by 2030. The report stated that India would require an investment of $ 10 billion into EV battery manufacturing and raw material refining industries if it wanted to meet domestic demand for Li-ion batteries by 2030.

The report stated that current India met 70% of its Li-ion battery needs through imports from China. The country current demand for Li-ion batteries stood at 3 GWh which is estimated to grow to 70 GWh by 2030.

Also read: Hero Vida Electric Scooter To Get Swappable Batteries

Barnik Chitran Maitra, Managing Partner, Arthur D Little, India, says “To accelerate India electric mobility growth, the government and the industry ecosystem must collaborate, to nurture a self-reliant, local EV value chain, with established battery manufacturers, OEMs, and start-ups, investing in continuous R&D, partnerships, and global alliances to create a strong supply chain. This, along with demand from customers, will turn India into a global EV powerhouse.”

India currently meets 70% of its demand for Li-Ion cells via imports

The report also cited some of the shortcomings of the current Indian EV industry. It stated that the country had an over-reliance on imports, limited local manufacturing and finite raw materials and raw material processing facilities.

Also read: Hero Electric To Set Up New EV Manufacturing Plant In Rajasthan

The report called on the government to implement new policies for the localisation of battery supply chains and provide improved access to raw materials. The report also said that the recently introduced PLI scheme for local battery manufacturing plans to jointly invest in lithium mines in Australia and increased customs duty on the import of Li-ion cells were all steps in the right direction

Also read: Tata Tiago EV Launched In India; Prices Start From Rs. 8.49 lakh

while citing that manufacturers needed to make heavy investments into research and development for battery technology such as safety and being economical and able to be manufactured in a large scale.

Latest News

Jaiveer Mehra | Mar 5, 2026Fourth-Gen Honda Insight Reborn As All-Electric CrossoverHonda claims the EV will offer a cruising range of over 500 km on the WLTC cycle.3 mins read

Jaiveer Mehra | Mar 5, 2026Fourth-Gen Honda Insight Reborn As All-Electric CrossoverHonda claims the EV will offer a cruising range of over 500 km on the WLTC cycle.3 mins read car&bike Team | Mar 5, 2026Hyundai Exter Facelift Spied Testing Ahead Of 2026 LaunchA partially disguised test mule of the facelifted Hyundai Exter has been spotted once again ahead of its expected launch later this year.2 mins read

car&bike Team | Mar 5, 2026Hyundai Exter Facelift Spied Testing Ahead Of 2026 LaunchA partially disguised test mule of the facelifted Hyundai Exter has been spotted once again ahead of its expected launch later this year.2 mins read Shams Raza Naqvi | Mar 5, 2026New-Gen Lexus ES Luxury Sedan To Be Launched In India On March 20Almost a year after its global debut, the Japanese luxury brand is bringing its newest sedan to the Indian market.1 min read

Shams Raza Naqvi | Mar 5, 2026New-Gen Lexus ES Luxury Sedan To Be Launched In India On March 20Almost a year after its global debut, the Japanese luxury brand is bringing its newest sedan to the Indian market.1 min read car&bike Team | Mar 5, 2026Ultraviolette Rolls Out Battery-As-A-Service; X-47 Now Available From Rs 1.49 LakhUltraviolette has launched a Battery Flex BaaS plan, with the X-47 starting at Rs 1.49 lakh and the F77 available from Rs 1.99 lakh.1 min read

car&bike Team | Mar 5, 2026Ultraviolette Rolls Out Battery-As-A-Service; X-47 Now Available From Rs 1.49 LakhUltraviolette has launched a Battery Flex BaaS plan, with the X-47 starting at Rs 1.49 lakh and the F77 available from Rs 1.99 lakh.1 min read Bilal Firfiray | Mar 5, 2026Maserati Delivers India’s First Bespoke Grecale Fuoriserie And One-Off GranCabrio TrofeoMaserati India has bought two bespoke Fuoriserie commissions – a Grecale GT in New Delhi and a GranCabrio Trofeo in Ahmedabad – showcasing the tailor-made preferences of the Indian customers.2 mins read

Bilal Firfiray | Mar 5, 2026Maserati Delivers India’s First Bespoke Grecale Fuoriserie And One-Off GranCabrio TrofeoMaserati India has bought two bespoke Fuoriserie commissions – a Grecale GT in New Delhi and a GranCabrio Trofeo in Ahmedabad – showcasing the tailor-made preferences of the Indian customers.2 mins read car&bike Team | Mar 4, 2026Kawasaki Patents Modular Electric Motorcycle PlatformWhile the concept of one chassis and multiple powertrains isn’t particularly new, it will allow for simplified production and pass savings onto the consumer.2 mins read

car&bike Team | Mar 4, 2026Kawasaki Patents Modular Electric Motorcycle PlatformWhile the concept of one chassis and multiple powertrains isn’t particularly new, it will allow for simplified production and pass savings onto the consumer.2 mins read

Bilal Firfiray | Feb 28, 2026Tata Punch EV Facelift Review: More Range, More Sense, Less MoneyThe Tata Punch EV facelift gets a bigger 40 kWh battery, faster 60 kW DC charging, improved thermal management, and better real-world range, and all of that at a lower introductory price. But does it become a more complete package now?6 mins read

Bilal Firfiray | Feb 28, 2026Tata Punch EV Facelift Review: More Range, More Sense, Less MoneyThe Tata Punch EV facelift gets a bigger 40 kWh battery, faster 60 kW DC charging, improved thermal management, and better real-world range, and all of that at a lower introductory price. But does it become a more complete package now?6 mins read Preetam Bora | Feb 24, 2026Hero Destini 110 Review: Simplicity, RefinedThe Hero Destini 110 is a no-nonsense commuter that is simple, comfortable and above all, fuel efficient. In 2026, when buyers are spoilt for choice, is it good enough to consider?6 mins read

Preetam Bora | Feb 24, 2026Hero Destini 110 Review: Simplicity, RefinedThe Hero Destini 110 is a no-nonsense commuter that is simple, comfortable and above all, fuel efficient. In 2026, when buyers are spoilt for choice, is it good enough to consider?6 mins read Preetam Bora | Feb 23, 2026TVS Apache RTX Road Test Review: Redefining the Entry-Level ADVAfter spending some time with the TVS Apache RTX in traffic, the daily commute, as well as on open highways, one thing becomes clear: the RTX is trying to redefine the entry-level ADV segment. But is it without fault?1 min read

Preetam Bora | Feb 23, 2026TVS Apache RTX Road Test Review: Redefining the Entry-Level ADVAfter spending some time with the TVS Apache RTX in traffic, the daily commute, as well as on open highways, one thing becomes clear: the RTX is trying to redefine the entry-level ADV segment. But is it without fault?1 min read Girish Karkera | Feb 20, 2026Road Test: 2025 VinFast VF7 AWD Sky InfinityFlagship all-electric SUV from the Vietnamese car maker gets most of the basics right.1 min read

Girish Karkera | Feb 20, 2026Road Test: 2025 VinFast VF7 AWD Sky InfinityFlagship all-electric SUV from the Vietnamese car maker gets most of the basics right.1 min read Jaiveer Mehra | Feb 18, 2026New BMW X3 30 Vs Mercedes-Benz GLC 300: Midsize Luxury SUV FaceoffWith the new X3 30, BMW has a direct competitor to the petrol GLC 300, but which is the luxury SUV for you?1 min read

Jaiveer Mehra | Feb 18, 2026New BMW X3 30 Vs Mercedes-Benz GLC 300: Midsize Luxury SUV FaceoffWith the new X3 30, BMW has a direct competitor to the petrol GLC 300, but which is the luxury SUV for you?1 min read