A Plastic Engine Capable of 450bhp

But now, there's something else brewing in the world of lightweight engines. There's one that is mostly made from plastic and will be tested in a racing car in 2016. US engineer Matti Holtzberg has teamed up with Belgian chemical company Solvay to work on the Polimotor 2 project which will see the birth of a powerful plastic engine.

Holtzberg, the president of Florida-based Composite Castings, had success with his first Polimotor engines in 1982, when they were used in an Amoco Chemical Company-sponsored racing car. The engine was based on a 2.0-litre Cosworth BDA engine which churned out 290bhp. There were plastic parts in this engine and these were the engine block, cam cover, intake valve stems, piston skirts, valve spring retainers, timing gears among others. Thanks to these components, the engine weighed in at 84 kg, which was half the weight when compared to the one with metal parts.

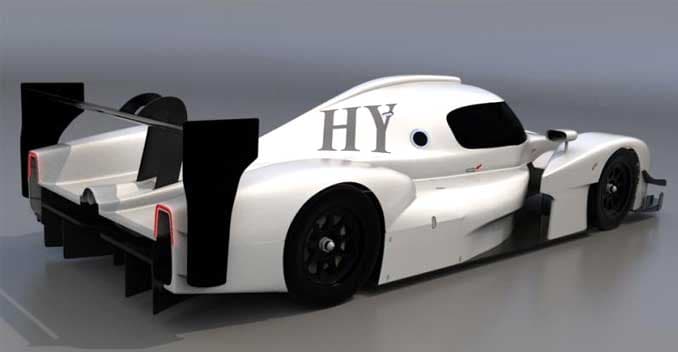

The Polimotor 2 takes things to a new level altogether. The engine is a four-cylinder, double-overhead CAM and will be installed in a Norma M-20 concept car which will compete at Lime Rock Park, Connecticut.

All that said, onto the big questions - Plastic in an Engine? How safe is it? Will it melt? Well no, it won't because certain components are made out of plastic. The exhaust port and the combustion chamber is an aluminium casting that's moulded into the cylinder head and then the pistons run in either a cast iron or a nikasil-coated bore. So, there is metal where the heat is; the rest is made out of composite material.

Solvay will provide up to 10 thermoplastic components which will replace the metal parts and these include the water pump, oil pump, water inlet/outlet, throttle body, fuel rail and cam sprockets. The engine will also feature a plastic turbocharger and an improved fuel injection system. Yes, it'll be powerful and will be capable of churning out 450bhp at 8000 rpm.

The entire development will be aimed at making an engine that weighs just about 63-67kg. There is still a lot of happening on the engine front and there are a number of technical issues to overcome, but if everything goes according to plan, this could very clearly be the future of engines.

Latest News

car&bike Team | Mar 6, 2026QJ Motor SRK 421 RR Unveiled In EuropeThe SRK 421 RR is powered by a high-revving, liquid-cooled, 421 cc, inline-four engine which makes 76 bhp at 14,000 rpm and 39 Nm at 13,000 rpm.1 min read

car&bike Team | Mar 6, 2026QJ Motor SRK 421 RR Unveiled In EuropeThe SRK 421 RR is powered by a high-revving, liquid-cooled, 421 cc, inline-four engine which makes 76 bhp at 14,000 rpm and 39 Nm at 13,000 rpm.1 min read Shams Raza Naqvi | Mar 6, 2026Batman Returns: Mahindra To Reopen Bookings For BE 6 Batman EditionMahindra had first launched the Batman in August 2025 when all 999 units got sold out in no time.2 mins read

Shams Raza Naqvi | Mar 6, 2026Batman Returns: Mahindra To Reopen Bookings For BE 6 Batman EditionMahindra had first launched the Batman in August 2025 when all 999 units got sold out in no time.2 mins read car&bike Team | Mar 6, 2026JSW’s Creta Electric Rival Spotted: Chery Jaecoo J5 Undergoes Testing In PuneThe upcoming JSW Motors SUV will be based on the Jaecoo J5 that is built by China’s Chery Automobile.1 min read

car&bike Team | Mar 6, 2026JSW’s Creta Electric Rival Spotted: Chery Jaecoo J5 Undergoes Testing In PuneThe upcoming JSW Motors SUV will be based on the Jaecoo J5 that is built by China’s Chery Automobile.1 min read car&bike Team | Mar 6, 2026Affordable New Honda Electric Motorcycle Revealed In PatentsPatent images reveal what appears to be Honda’s future strategy for the electric motorcycle segment – another low-cost electric motorcycle.3 mins read

car&bike Team | Mar 6, 2026Affordable New Honda Electric Motorcycle Revealed In PatentsPatent images reveal what appears to be Honda’s future strategy for the electric motorcycle segment – another low-cost electric motorcycle.3 mins read Jaiveer Mehra | Mar 5, 2026Fourth-Gen Honda Insight Reborn As All-Electric CrossoverHonda claims the EV will offer a cruising range of over 500 km on the WLTC cycle.3 mins read

Jaiveer Mehra | Mar 5, 2026Fourth-Gen Honda Insight Reborn As All-Electric CrossoverHonda claims the EV will offer a cruising range of over 500 km on the WLTC cycle.3 mins read car&bike Team | Mar 5, 2026Hyundai Exter Facelift Spied Testing Ahead Of 2026 LaunchA partially disguised test mule of the facelifted Hyundai Exter has been spotted once again ahead of its expected launch later this year.2 mins read

car&bike Team | Mar 5, 2026Hyundai Exter Facelift Spied Testing Ahead Of 2026 LaunchA partially disguised test mule of the facelifted Hyundai Exter has been spotted once again ahead of its expected launch later this year.2 mins read

Bilal Firfiray | Feb 28, 2026Tata Punch EV Facelift Review: More Range, More Sense, Less MoneyThe Tata Punch EV facelift gets a bigger 40 kWh battery, faster 60 kW DC charging, improved thermal management, and better real-world range, and all of that at a lower introductory price. But does it become a more complete package now?6 mins read

Bilal Firfiray | Feb 28, 2026Tata Punch EV Facelift Review: More Range, More Sense, Less MoneyThe Tata Punch EV facelift gets a bigger 40 kWh battery, faster 60 kW DC charging, improved thermal management, and better real-world range, and all of that at a lower introductory price. But does it become a more complete package now?6 mins read Preetam Bora | Feb 24, 2026Hero Destini 110 Review: Simplicity, RefinedThe Hero Destini 110 is a no-nonsense commuter that is simple, comfortable and above all, fuel efficient. In 2026, when buyers are spoilt for choice, is it good enough to consider?6 mins read

Preetam Bora | Feb 24, 2026Hero Destini 110 Review: Simplicity, RefinedThe Hero Destini 110 is a no-nonsense commuter that is simple, comfortable and above all, fuel efficient. In 2026, when buyers are spoilt for choice, is it good enough to consider?6 mins read Preetam Bora | Feb 23, 2026TVS Apache RTX Road Test Review: Redefining the Entry-Level ADVAfter spending some time with the TVS Apache RTX in traffic, the daily commute, as well as on open highways, one thing becomes clear: the RTX is trying to redefine the entry-level ADV segment. But is it without fault?1 min read

Preetam Bora | Feb 23, 2026TVS Apache RTX Road Test Review: Redefining the Entry-Level ADVAfter spending some time with the TVS Apache RTX in traffic, the daily commute, as well as on open highways, one thing becomes clear: the RTX is trying to redefine the entry-level ADV segment. But is it without fault?1 min read Girish Karkera | Feb 20, 2026Road Test: 2025 VinFast VF7 AWD Sky InfinityFlagship all-electric SUV from the Vietnamese car maker gets most of the basics right.1 min read

Girish Karkera | Feb 20, 2026Road Test: 2025 VinFast VF7 AWD Sky InfinityFlagship all-electric SUV from the Vietnamese car maker gets most of the basics right.1 min read Jaiveer Mehra | Feb 18, 2026New BMW X3 30 Vs Mercedes-Benz GLC 300: Midsize Luxury SUV FaceoffWith the new X3 30, BMW has a direct competitor to the petrol GLC 300, but which is the luxury SUV for you?1 min read

Jaiveer Mehra | Feb 18, 2026New BMW X3 30 Vs Mercedes-Benz GLC 300: Midsize Luxury SUV FaceoffWith the new X3 30, BMW has a direct competitor to the petrol GLC 300, but which is the luxury SUV for you?1 min read