Aston Martin Starts Production of DB11's V12 at Engine Plant in Germany

- The DB11's V12 engine was designed in-house

- Each engine is built by one assembly technician

- The AMEP has a production capacity of 8,000 engines a year

Aston Martin DB11's new 5.2L twin-turbo V12 engine has entered full production at the British carmaker's engine plant in Cologne, Germany. The landmark has been reached with the DB11's new 5.2L twin-turbo V12 entering full production. Aston Martin showcased the DB9 successor earlier this year at the Geneva Motor Show 2016. One must note, the DB11 is based on the DBX concept and the DB10 developed specifically for James Bond movie Spectre.

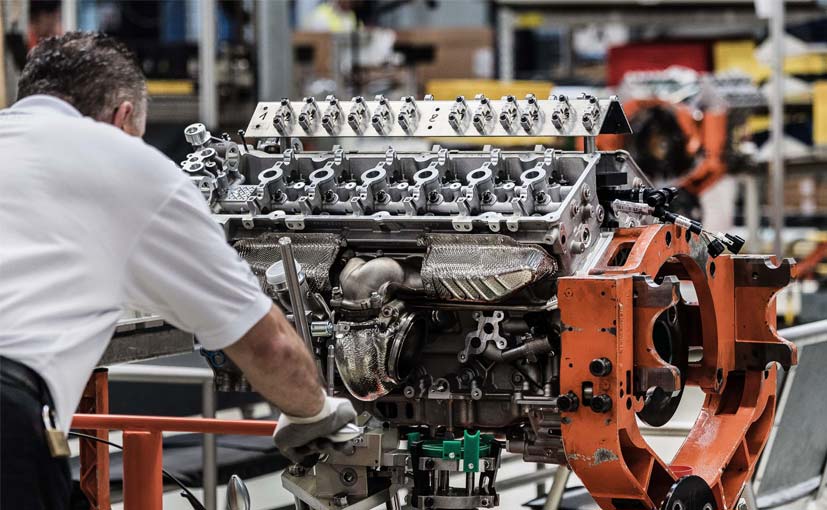

(The V12 motor develops 600bhp and 700Nm of torque)

Brian Fitzsimons, Aston Martin Chief Engineer, Powertrain, said, "To see this new engine go into full production at AMEP makes me very proud. Designing and developing the 5.2L twin-turbo power plant has been an all-consuming passion for me and my team. Knowing that the end result would be built with meticulous care in a truly state-of-the-art facility such as AMEP was an added motivation. It's a hugely exciting time to be an engineer at Aston Martin, not least because this is just the beginning for the new twin-turbo V12."

Designed in-house, the Aston Martin DB11's V12 motor develops 600bhp and 700Nm of torque, making it the most powerful production DB model ever. With a top-speed of 322Km/h, it is also the fastest. Oh, and it can also go from standstill to 100Km/h in just 3.9 seconds.

(The Aston Martin Engine Plant has a production capacity of 8,000 engines a year)

The Aston Martin Engine Plant (AMEP), opened in 2004, is a dedicated solely to the production of Aston Martin power plants. To ensure the highest levels of quality and consistency, one engine assembly technician builds each engine, following the process through from start to finish. It takes a total of 8 hours to build one V12 engine and each engine undergoes stringent cold and hot testing within the facility. The AMEP has a production capacity of 8,000 engines a year, where production of the 6.0L V12 and 4.7L V8 engines will also continue.

Dr. Andy Palmer, Aston Martin President and CEO, commented, "AMEP is one of our great success stories and one of the jewels in the Aston Martin crown. To have the ability to design and then manufacture our own high-performance engines in-house is something very special. It gives us ultimate control of quality and that all-important character for which Aston Martin cars are renowned. I have no doubts that our new twin-turbo V12 is the start of an even greater era of success."

Latest News

Jaiveer Mehra | Jan 8, 2026Auto Sales 2025: BMW Group India Sold 18,001 Cars And SUVs, Its Highest Ever Yearly FigureCarmaker delivered 17,271 units under the BMW brand and 730 units under Mini.1 min read

Jaiveer Mehra | Jan 8, 2026Auto Sales 2025: BMW Group India Sold 18,001 Cars And SUVs, Its Highest Ever Yearly FigureCarmaker delivered 17,271 units under the BMW brand and 730 units under Mini.1 min read car&bike Team | Jan 8, 2026Suzuki Motorcycle India Achieves 10 Million Production MilestoneThe 10 millionth unit was an Access 125 scooter, which rolled out from Suzuki’s Gurugram plant.1 min read

car&bike Team | Jan 8, 2026Suzuki Motorcycle India Achieves 10 Million Production MilestoneThe 10 millionth unit was an Access 125 scooter, which rolled out from Suzuki’s Gurugram plant.1 min read Jaiveer Mehra | Jan 8, 2026Tata Safari Petrol vs Mahindra XUV 7XO : Specs, Features ComparedTata has finally introduced a petrol engine option on the Safari for the 2026 model year, but how does it compare to the popular Mahindra XUV 7XO?1 min read

Jaiveer Mehra | Jan 8, 2026Tata Safari Petrol vs Mahindra XUV 7XO : Specs, Features ComparedTata has finally introduced a petrol engine option on the Safari for the 2026 model year, but how does it compare to the popular Mahindra XUV 7XO?1 min read car&bike Team | Jan 8, 20262026 World Car Awards Finalists AnnouncedThe winners of the awards will be announced on April 1 at the 2026 New York Auto Show.1 min read

car&bike Team | Jan 8, 20262026 World Car Awards Finalists AnnouncedThe winners of the awards will be announced on April 1 at the 2026 New York Auto Show.1 min read car&bike Team | Jan 8, 2026KTM RC 160 Launched In India At Rs 1.85 LakhThe RC 160 serves as the entry point in KTM India's supersport range.2 mins read

car&bike Team | Jan 8, 2026KTM RC 160 Launched In India At Rs 1.85 LakhThe RC 160 serves as the entry point in KTM India's supersport range.2 mins read car&bike Team | Jan 8, 2026Pioneer Ride Connect To Debut As Phone-First Motorcycle Dashboard PlatformPioneer Ride Connect previews a future where motorcycle dashboards rely on smartphones, cloud navigation and voice control instead of standalone hardware.1 min read

car&bike Team | Jan 8, 2026Pioneer Ride Connect To Debut As Phone-First Motorcycle Dashboard PlatformPioneer Ride Connect previews a future where motorcycle dashboards rely on smartphones, cloud navigation and voice control instead of standalone hardware.1 min read

Bilal Firfiray | Jan 9, 2026Toyota Urban Cruiser Hyryder: 10,000 km Long-Term ReviewAfter spending over three months and 10,000 km with the Toyota Urban Cruiser Hyryder Hybrid, we were impressed by its real-world mileage, seamless hybrid, practical comfort, and Toyota reliability. Is it the best C-SUV then?5 mins read

Bilal Firfiray | Jan 9, 2026Toyota Urban Cruiser Hyryder: 10,000 km Long-Term ReviewAfter spending over three months and 10,000 km with the Toyota Urban Cruiser Hyryder Hybrid, we were impressed by its real-world mileage, seamless hybrid, practical comfort, and Toyota reliability. Is it the best C-SUV then?5 mins read Seshan Vijayraghvan | Jan 8, 20262026 Mahindra XUV 7XO Review: Big On Tech, Bigger On ComfortThe new Mahindra XUV 7XO is flashier, feature packed, and comes with more advanced tech. But are the changes just incremental or actually substantial?1 min read

Seshan Vijayraghvan | Jan 8, 20262026 Mahindra XUV 7XO Review: Big On Tech, Bigger On ComfortThe new Mahindra XUV 7XO is flashier, feature packed, and comes with more advanced tech. But are the changes just incremental or actually substantial?1 min read Amaan Ahmed | Jan 3, 2026VLF Mobster 135 300 KM Review: Fun But FlawedA 125 cc scooter with Italian design and Chinese genes is a rare combination, and while some may be tempted to dismiss it because of its origins, the VLF Mobster shows 125s can also be exciting – but not without compromises.11 mins read

Amaan Ahmed | Jan 3, 2026VLF Mobster 135 300 KM Review: Fun But FlawedA 125 cc scooter with Italian design and Chinese genes is a rare combination, and while some may be tempted to dismiss it because of its origins, the VLF Mobster shows 125s can also be exciting – but not without compromises.11 mins read Preetam Bora | Dec 30, 2025TVS Orbiter Review: Real-World Performance and Range TestedThe TVS Orbiter is a promising electric scooter promising decent range, practicality and pricing. But is there any reason to avoid it? We spent a few days getting to know it better.9 mins read

Preetam Bora | Dec 30, 2025TVS Orbiter Review: Real-World Performance and Range TestedThe TVS Orbiter is a promising electric scooter promising decent range, practicality and pricing. But is there any reason to avoid it? We spent a few days getting to know it better.9 mins read Jafar Rizvi | Dec 24, 2025MG Windsor EV 38 kWh Long-Term Report: IntroductionThe Windsor EV has joined our garage, and before it settles into daily duty, I took it out to get a sense of what living with an electric car is like.4 mins read

Jafar Rizvi | Dec 24, 2025MG Windsor EV 38 kWh Long-Term Report: IntroductionThe Windsor EV has joined our garage, and before it settles into daily duty, I took it out to get a sense of what living with an electric car is like.4 mins read