BMW Motorrad Carbon Fibre Swingarm Wins Innovation Award

- The carbon fibre swingarm is yet to be implemented in a production model

- The swingarm uses carbon fibre plastic and additional reinforcements

- The new swingarm design is expected to be affordable

BMW Motorrad has won the 2018 JEC Innovation Award in the Sports and Leisure category for the development and manufacture of a rear swingarm made of carbon fibre. The JEC Group is the world's leading specialist organisation in composite material development and manufacture. The award-winning swingarm from BMW is of a modular design, made of carbon-fibre and additional reinforcement materials. This allows the swingarm to be used for different demands, using a single injection mould. And despite it using carbon fibre, the design is scalable and has reduced costs to make it affordable to be used in a wide variety of motorcycles.

The swingarm project was intended to develop a system to allow mass production of carbon fibre in structural components. The project was sponsored by the German Federal Ministry of Education and Research as part of the leading-age cluster MAI-Carbon. The aim of the project, involving seven partners from industry and research, was to develop a process that enabled the cost-effective, volume production use of carbon fibre composite materials (CFP) in structural components subject to high levels of continuous stress.

For the carbon fibre swingarm, it was possible to establish a cost-efficient manufacturing process suitable for large-scale production of injection mould components made of carbon fibre reinforced plastic with carbon fibre tape reinforcements.

Project Manager Elmar Jager explained, "We opted for chassis components under continuous load since the requirements involved are especially demanding. While car chassis parts are concealed, the visible motorcycle rear swingarm was ideal for our project since the forces at work are immediately evident. Our production technique uses CFP in the form of high-strength endless fibres where this is required by the stress pattern, while an injection mould part with short CFP recycling fibres is used where the stress levels are not as high. In this way, we developed a cost-efficient design that can be scaled according to requirements by inserting endless fibres with varying levels of strength in the same tool."

"These were the points that impressed the international jury. The insights we gained from this motorcycle component are equally valuable from the point of view of car development and can be applied accordingly."

The BMW Group uses lightweight construction in both automobiles and motorcycles, applying an intelligent combination of different materials including carbon fibre as a particularly important element. The latest example from BMW Motorrad was the HP4 RACE, where the entire main frame was made of carbon fibre reinforced plastic produced by means of an industrial RTM process. In 2017 the carbon fibre frame of the HP4 RACE opened a whole new chapter in motorcycle chassis construction, combining optimum technical qualities, uniform manufacturing quality and cost efficiency for the first time.

So far, the carbon fibre swingarm has not been introduced on any production motorcycle, but expect BMW Motorrad to introduce an updated HP4 RACE with the new swingarm.

Latest News

car&bike Team | Feb 2, 2026Car Sales January 2026: Six Marutis in Top 10, But Tata Nexon Takes Top SpotTata Motors sold 23,365 units of the Nexon, creating a clear gap to the Maruti Suzuki Dzire, which finished second with 19,629 units.1 min read

car&bike Team | Feb 2, 2026Car Sales January 2026: Six Marutis in Top 10, But Tata Nexon Takes Top SpotTata Motors sold 23,365 units of the Nexon, creating a clear gap to the Maruti Suzuki Dzire, which finished second with 19,629 units.1 min read car&bike Team | Feb 2, 2026Maruti Suzuki Victoris Crosses 50,000 Sales Milestone In 4 monthsThe compact SUV launched at the onset of festive season has crossed the 50,000 sales mark in about 4 months1 min read

car&bike Team | Feb 2, 2026Maruti Suzuki Victoris Crosses 50,000 Sales Milestone In 4 monthsThe compact SUV launched at the onset of festive season has crossed the 50,000 sales mark in about 4 months1 min read car&bike Team | Feb 2, 2026Two-Wheeler Sales January 2026: Hero MotoCorp, TVS, Royal Enfield, Suzuki Report Sustained GrowthMost brands have reported year-on-year growth in the first month of CY26.2 mins read

car&bike Team | Feb 2, 2026Two-Wheeler Sales January 2026: Hero MotoCorp, TVS, Royal Enfield, Suzuki Report Sustained GrowthMost brands have reported year-on-year growth in the first month of CY26.2 mins read car&bike Team | Feb 2, 2026Maruti Suzuki Announces Price Protection Amid Long Waiting PeriodsCountry’s largest carmaker has said that prices of the cars will not be increased for customers who have already made the bookings1 min read

car&bike Team | Feb 2, 2026Maruti Suzuki Announces Price Protection Amid Long Waiting PeriodsCountry’s largest carmaker has said that prices of the cars will not be increased for customers who have already made the bookings1 min read Jafar Rizvi | Feb 2, 2026Yamaha EC-06 vs River Indie: How Different Are The Two Electric Scooters?The EC-06 shares its foundation with the River Indie, and here we look at the differences between the two.3 mins read

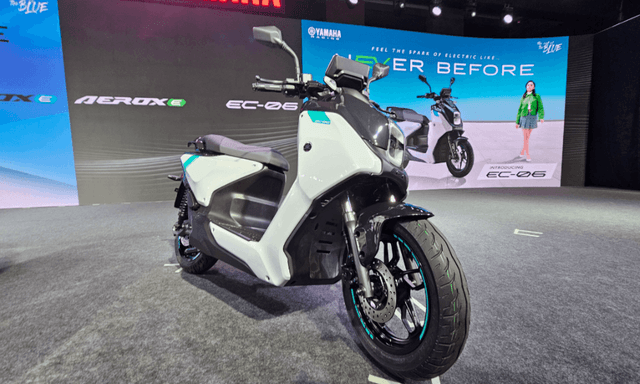

Jafar Rizvi | Feb 2, 2026Yamaha EC-06 vs River Indie: How Different Are The Two Electric Scooters?The EC-06 shares its foundation with the River Indie, and here we look at the differences between the two.3 mins read Jafar Rizvi | Feb 2, 2026Yamaha EC-06 E-Scooter Launched In India At Rs 1.68 LakhThe EC-06 marks Yamaha’s entry into the electric scooter segment in India.2 mins read

Jafar Rizvi | Feb 2, 2026Yamaha EC-06 E-Scooter Launched In India At Rs 1.68 LakhThe EC-06 marks Yamaha’s entry into the electric scooter segment in India.2 mins read

Preetam Bora | Feb 2, 2026TVS NTorq 150 Road Test Review: Bigger, Better & More Efficient!We test the new TVS NTorq 150 out in the real world to get a sense of what it offers in terms of performance, dynamics and fuel economy.7 mins read

Preetam Bora | Feb 2, 2026TVS NTorq 150 Road Test Review: Bigger, Better & More Efficient!We test the new TVS NTorq 150 out in the real world to get a sense of what it offers in terms of performance, dynamics and fuel economy.7 mins read Bilal Firfiray | Jan 21, 2026Tata Punch Facelift Review: New Turbo Engine; Same Old SoulWith the update, the Tata Punch facelift retains its character of being a healthy runabout, which is perfect for Indian roads. But have these changes made it any better?7 mins read

Bilal Firfiray | Jan 21, 2026Tata Punch Facelift Review: New Turbo Engine; Same Old SoulWith the update, the Tata Punch facelift retains its character of being a healthy runabout, which is perfect for Indian roads. But have these changes made it any better?7 mins read Amaan Ahmed | Jan 17, 2026Bajaj Chetak C25 First Ride Review: Basic, Likeable E-Scooter For First-Time RidersThe Chetak C25, in quite a few ways, is poles apart from the larger and more powerful 30 and 35 Series models, but in its mannerisms, it is very much a Chetak.8 mins read

Amaan Ahmed | Jan 17, 2026Bajaj Chetak C25 First Ride Review: Basic, Likeable E-Scooter For First-Time RidersThe Chetak C25, in quite a few ways, is poles apart from the larger and more powerful 30 and 35 Series models, but in its mannerisms, it is very much a Chetak.8 mins read Bilal Firfiray | Jan 9, 2026Toyota Urban Cruiser Hyryder: 10,000 km Long-Term ReviewAfter spending over three months and 10,000 km with the Toyota Urban Cruiser Hyryder Hybrid, we were impressed by its real-world mileage, seamless hybrid, practical comfort, and Toyota reliability. Is it the best C-SUV then?5 mins read

Bilal Firfiray | Jan 9, 2026Toyota Urban Cruiser Hyryder: 10,000 km Long-Term ReviewAfter spending over three months and 10,000 km with the Toyota Urban Cruiser Hyryder Hybrid, we were impressed by its real-world mileage, seamless hybrid, practical comfort, and Toyota reliability. Is it the best C-SUV then?5 mins read Seshan Vijayraghvan | Jan 8, 20262026 Mahindra XUV 7XO Review: Big On Tech, Bigger On ComfortThe new Mahindra XUV 7XO is flashier, feature packed, and comes with more advanced tech. But are the changes just incremental or actually substantial?1 min read

Seshan Vijayraghvan | Jan 8, 20262026 Mahindra XUV 7XO Review: Big On Tech, Bigger On ComfortThe new Mahindra XUV 7XO is flashier, feature packed, and comes with more advanced tech. But are the changes just incremental or actually substantial?1 min read